Magnesium

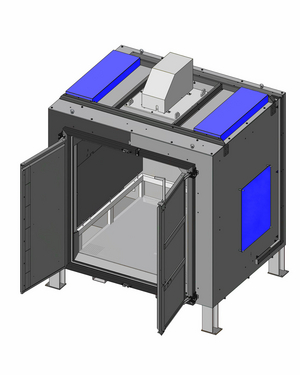

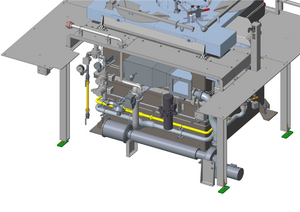

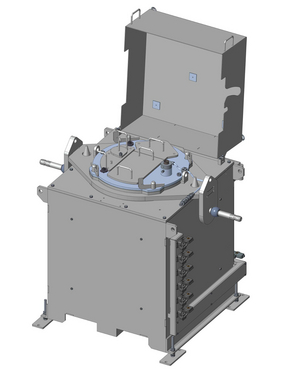

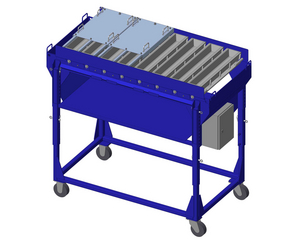

The ability to process Magnesium is becoming increasingly important. RAUCH specialises in the complex requirements of Magnesium in solid and liquid form and it offers individual complete solutions – from co-development through to implementation and follow-up support. Whether it is optimising existing systems or a new project – the expert team at RAUCH provides the decisive edge with the latest research findings and pioneering experience in the Magnesium sector!

RAUCH systems prove their worth globally with high availability, low energy and maintenance costs and simple handling. Of course, RAUCH systems ensure extremely precise dosing and the highest level of safety.

In addition to standard applications, RAUCH also provides solutions for sand casting, continuous casting and low-pressure applications.