Non-ferrous metals

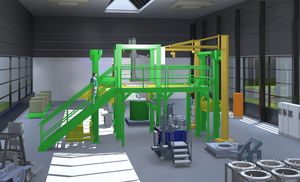

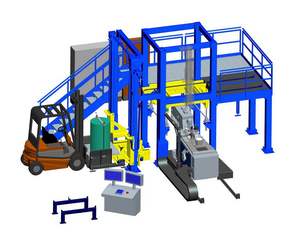

Non-ferrous metals save costs and weight. Whether in the automotive sector, in aerospace or in the IT industry, the need for parts made from non-ferrous metals is continuously increasing! Various alloys and methods are used to produce superior products – in this respect, RAUCH is a reliable partner with a broad range of products and profound know-how in the processing of Aluminium, lead and a large number of other non-ferrous metals.

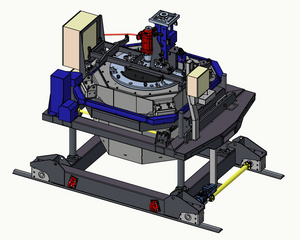

With regard to gravity casting and low-pressure casting, the universally applicable melting furnaces, containers and dosage systems developed by RAUCH impress with powerful technology from the Magnesium sector. Due to the many processing possibilities of lead, the melting experts at RAUCH have also developed a wide range of internal rotary and machine furnaces.