Zinc

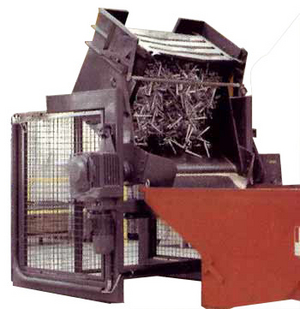

Cost advantages in the foundry are competitive advantages on the market. Therefore, the expert team at RAUCH develops and produces sustainable efficiency-enhancing solutions: The optimisation of casting conditions through the provision of Zinc at a constant level and constant temperature and the re-melting of runner and biscuits reduces operating costs and increases productivity. In particular, the integration of in-plant recycling systems also reduces costs by eliminating external re-melting, transport and interim storage costs and through savings in raw material storage.

The recycling material, which is comparable to the new material in terms of quality, can be either automatically cast as ingots in a RAUCH system or more economically introduced in the production process!