Zinc die casting allows the efficient production of large quantities with just one casting mold. The low melting point of zinc (390° C) and the particularly narrow solidification interval allow tight tolerances and demanding surfaces. The result is very small to medium-sized castings, even in the case of complicated shapes, with maximum precision, hardness and strength - but this requires optimum casting conditions such as a constant filling and an exact temperature level. RAUCH provides precisely these conditions with its specially designed zinc casting solutions.

Hot-chamber Machine Furnace ZMO

Melting Furnace ZSO

Melt Container ZSB

Conveyor Belt ZFB

Ingot Casting Belt ZMGB

Liquid Transport System ZFTS

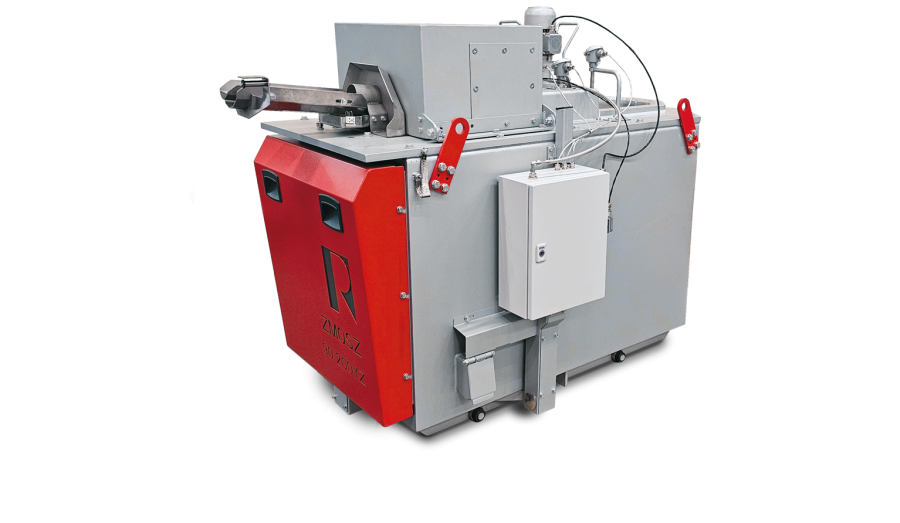

Hot-chamber Machine Furnace ZMO

The RAUCH Zinc Machine Furnace ZMO impresses by its advanced technology and practicality. It efficiently melts and keeps zinc alloys hot, ideal for aluminum content below 5%. A two-chamber design guarantees consistent casting quality and seamless integration into hot-chamber die casting processes.

- High melting capacity: Efficient melting and holding of zinc alloys

- Two-chamber technology: Continuous melt level for consistent casting quality

- Versatility: Ideal for ingots and liquid charging

- Seamless integration: Perfect integration into hot-chamber die casting machines for optimized production processes

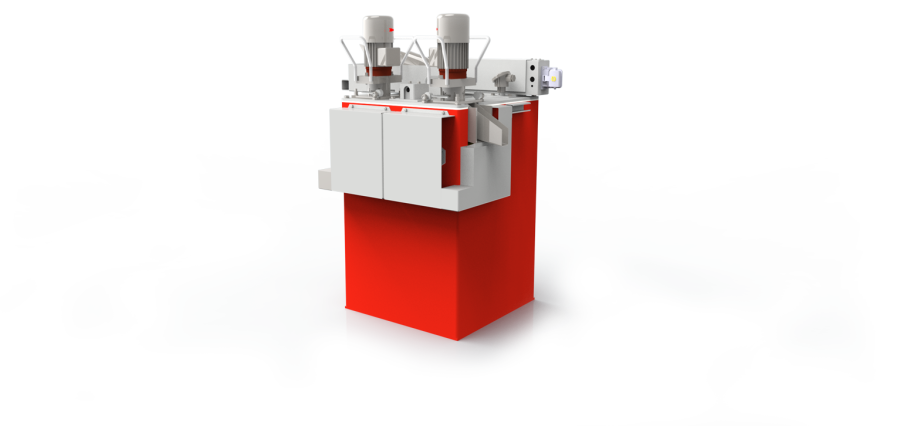

Melting Furnace ZSO: up to 1000 kg/h, electric or combustion-fired

The RAUCH Zinc Melting Furnaces ZSO offer advanced solutions for melting and remelting zinc alloys. Both models are characterized by their robust design and innovative technology, which enable reliable processing and recycling of zinc.

- Efficient remelting: Enables the complete remelting of overflows, air beans, sprues and rejects

- Energy efficiency: The RAUCH recuperator technology in the ZSO reduces energy consumption by up to 30 % through efficient fuel utilization and heat recovery

- Precise and safe control: Real-time monitoring and exact control of the feeding system by weighing equipment and PLC control ensure precise and safe operation

- Constant temperature control: Guarantees a constant temperature level thanks to the indirect electrical heating of the pump chamber, which ensures uniform processing and a constant material flow

Melt Container ZSB

The RAUCH Zinc Melt Container ZSB is ideal for transporting and maintaining the temperature of zinc die-casting alloys. With high-quality insulation and efficient heating technology, it ensures optimal storage and transport conditions.

- indirect electric bottom heating for uniform heat distribution

- Flexibility thanks to one or two filling funnels and pump systems

- optional platform with weight measurement for precise level control

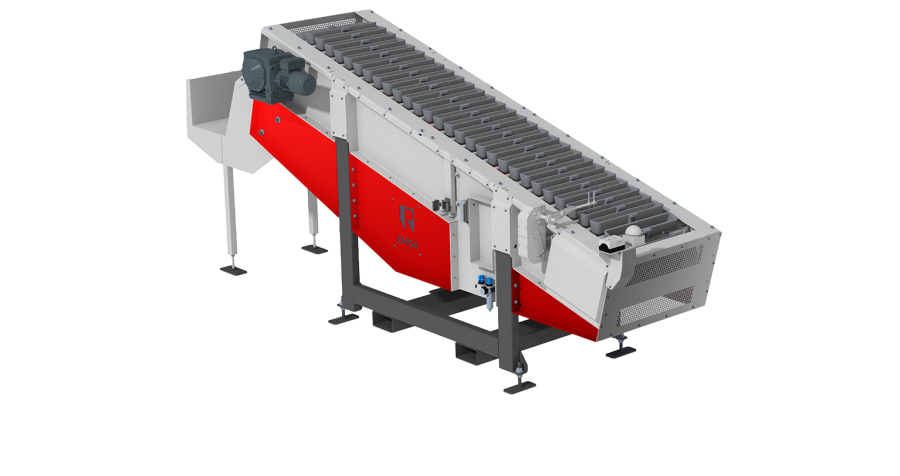

Conveyor Belt ZFB

The RAUCH Zinc Conveyor Belt ZFB ensures the continuous feeding of melting furnaces with circulating material. It enables an efficient and reliable material supply and thus supports a smooth production process.

- Continuous feeding: Ensuring a constant flow of material into the melting furnace

- High capacity: Intermediate storage of up to 500 kg of recycled material

- Robust construction: Steel hinged plate belt and large-volume feeding hopper for long-lasting use

- Noise reduction: Noise insulation panels in the feeding hopper for quiet operation

- Safety: Torque monitor and reversing circuit protect against overload

Ingot Casting Belt ZMGB

The RAUCH Zinc Ingot Casting Belt ZMGB optimizes the automated casting of recycled material from melting furnaces. This state-of-the-art system ensures efficiency and reliability in metal processing.

- reliable drive with a powerful helical gear motor

- flexible level sensor system with pneumatic actuation

- versatile filling of ingot molds possible from both sides

Zinc Liquid Transport System ZFTS: Efficiency and flexibility redefined

The RAUCH ZFTS revolutionizes melt transport in your foundry. This fully automated system ensures a reliable supply of liquid zinc to your Zinc Machine Furnaces (ZMO) from a central Melting Furnace (ZSO). By integrating the autonomous mobile robot (AMR) from AGILOX, it guarantees efficient and secure material flow—24/7.

- Fully automated: Works regardless of staff shortages

- High productivity: Optimized processes for pre- and post-melting furnaces

- Flexible layout: Positioning of furnaces as required

- Round-the-clock operation: Ideal for use in three-shift operation

- Excellent insulation: Ensures minimal temperature loss of the melting material (less than 8°C in 1 hour)

- Precise navigation: Contour-based control with +/- 2 mm accuracy

- Maximum security: ISO 3691-4 and UL certified technology for use in human-machine environments

- Expandability: Customization and integration of new workflows in just a few minutes