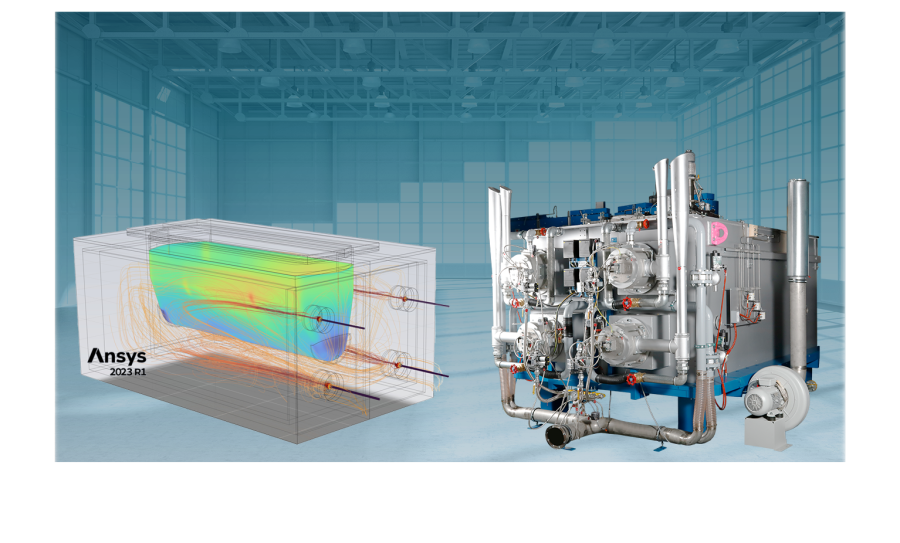

Predictive maintenance with RAUCH's digital twin

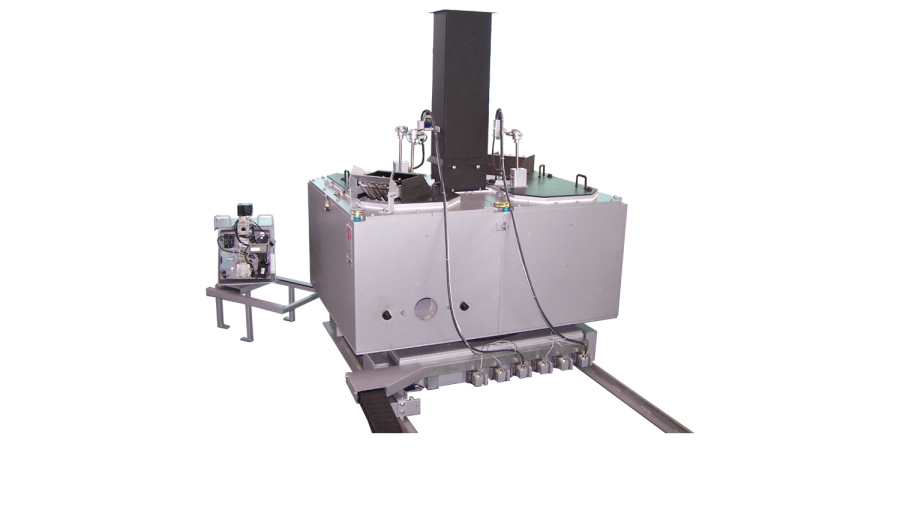

RAUCH's Digital Twin technology provides you with an advanced solution for the proactive maintenance of your melting systems. Our innovative technology enables precise real-time monitoring and analysis that detects potential problems before they occur. This ensures maximum uptime and minimizes downtime risks.

- Real-time monitoring and analysis: The Digital Twin continuously records and analyzes your system's operating data to monitor its status in real time and identify potential weak points at an early stage.

- Predictive maintenance: With the help of intelligent algorithms and predictive models, maintenance measures can be planned precisely to avoid unplanned downtime and maximize efficiency.

- Optimization of operating times: The Digital Twin enables precise control and adjustment of operating parameters, resulting in optimum utilization of the system and longer operating times.

- Focus on cost reduction: By precisely planning maintenance measures and avoiding unexpected breakdowns, the Digital Twin helps to reduce operating costs and increase profitability.

- The RAUCH Digital Twin is an indispensable technology for companies in the modern manufacturing industry that value maximum efficiency, low downtimes and a future-proof maintenance strategy.