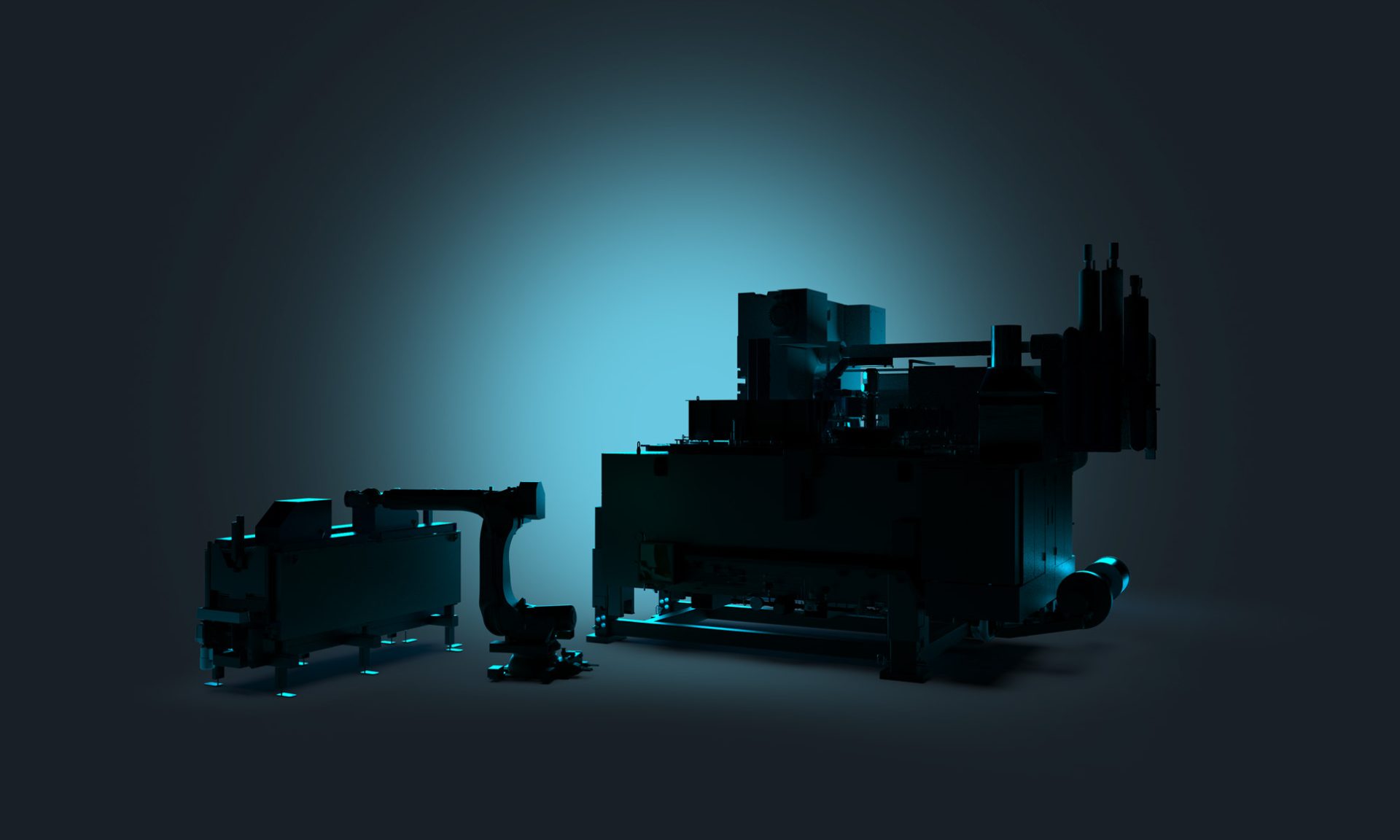

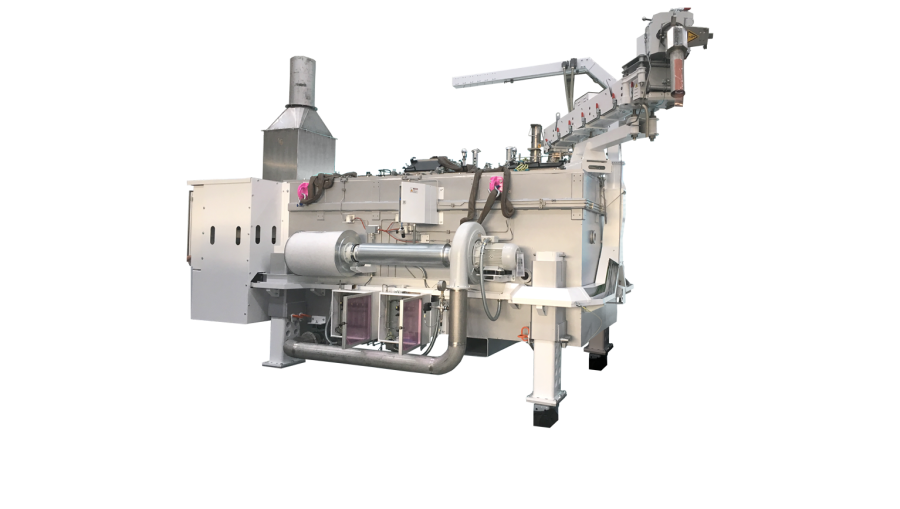

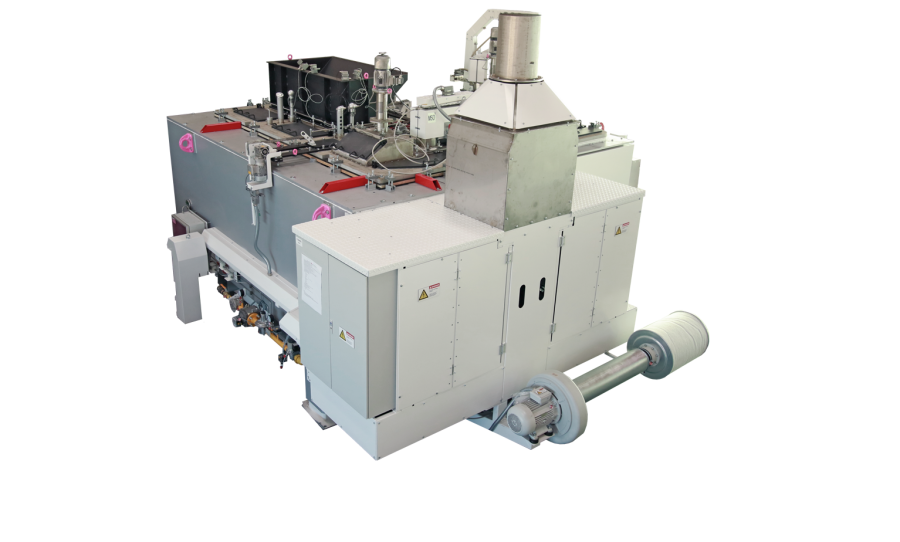

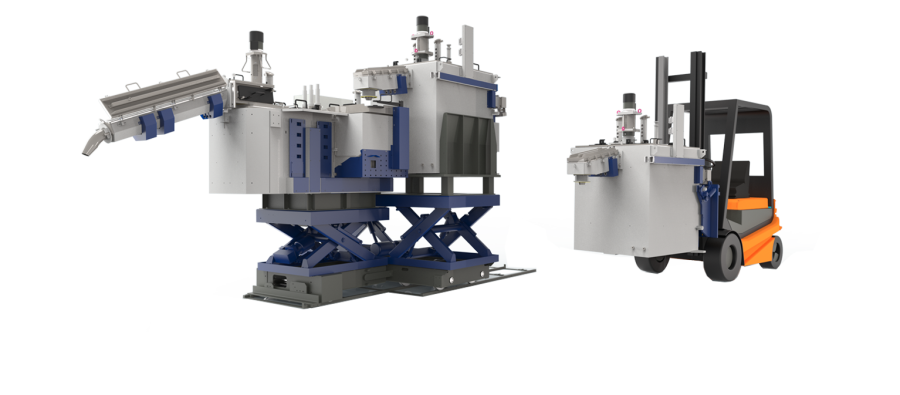

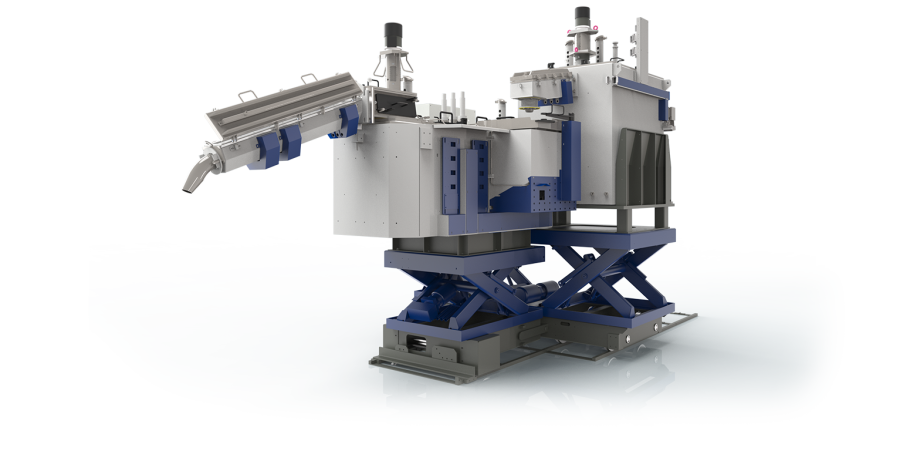

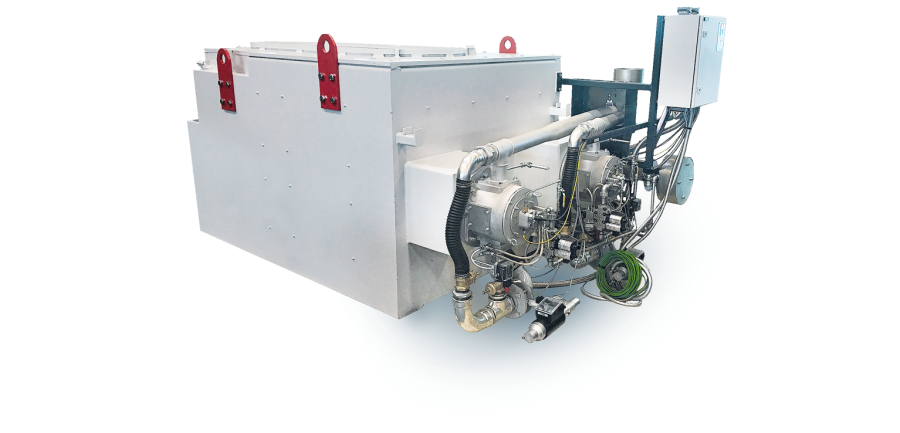

The RAUCH Magnesium Melting Furnace MSO offers a flexible solution for melting magnesium, making it ideal for applications such as incell recycling, liquid metal transport, alloying, and sheet casting systems. With a melting capacity of 650 to 1.500 kg/h, the MSO meets a wide range of production requirements. By utilizing protective gas in three separate, individually adjustable atmospheres, the melt handling process is optimized. The melt is transferred to downstream systems such as MDO, MSB, or MGO via a siphon or a variable-speed dosing pump, enabling efficient processing in subsequent equipment.

- Available melting capacities: 650 bis 1.500 kg/h

- Optimized Homogeneity: Stirrer or jet pump ensures even melt distribution

- Stable melt transfer: Melt is transferred via siphon or dosing pump to downstream systems

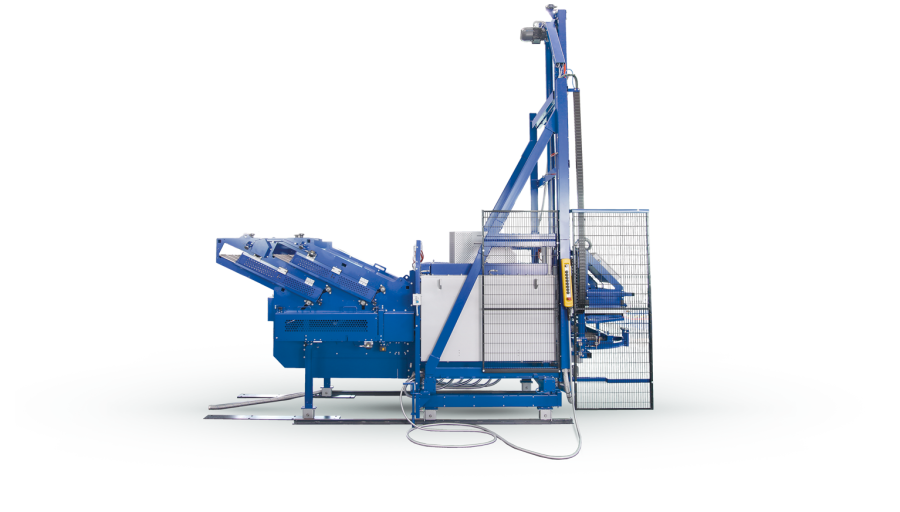

- Flexible Charging: Furnace can be charged using an Ingot Preheating Unit MVE or manual/automated addition of recycled materials such as sprues