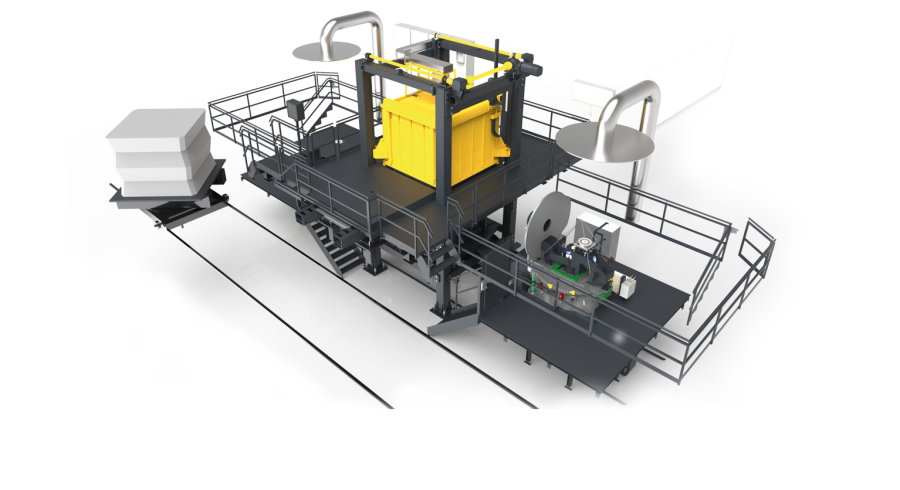

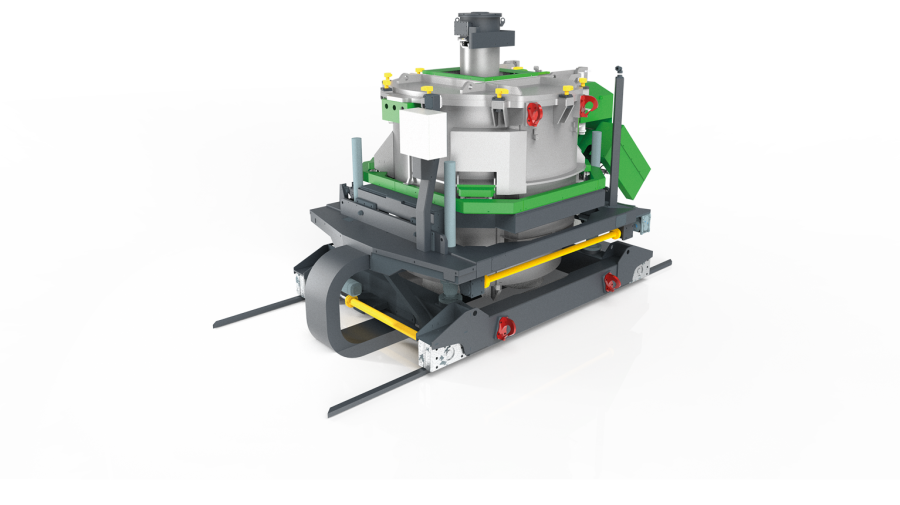

The RAUCH Magnesium Low Pressure Casting System (Mg NGS) revolutionizes casting technology by means of precise, turbulence-free mold filling using a magnesium pump. This innovative process allows the production of components in the gravity die or sand casting process with high filling speed and minimal inert gas consumption. The freely programmable filling curve and exact holding pressure control guarantee efficient and safe casting processes, even with complex mold channels and thick sections.

- Turbulence-free filling: The melt is fed into the mold without turbulence or gas inclusions

- Programmable filling curves: Adjustable filling rates and weight levels for precise casting

- High filling speed: Fast and efficient filling, even with thick-walled sections

- Low protective gas consumption: Cost-efficient processing of magnesium due to reduced need for protective gas

- Precise back-pressure control: Maintaining and applying back-pressure during solidification for optimal component quality