ECO-Jet

The term ECO Jet refers to a special system tuned to the RAUCH product range, which optimizes the feeding and melting process in magnesium dosing furnaces.

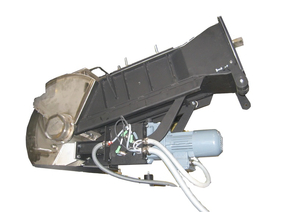

The system is based on principles from the registered patent (DE 10256513A1 - US 10/719142) and consists of

a tilt sluice for accepting common commercial ingot (this sluice can be feed by hand or with a ingot pre-heat system from RAUCH - MVE 150/500...),

- a melting shaft, which prevents the ingot in the melt from uncontrolled descent, and

- a “jet pump” from the registered patent (DE 10256513A1 - US 10/719142), which directs the melt on the one hand to the molten material and on the other hand along the crucible walls.

The system has the following economic advantages:

Less material loss through segregation (sump) and oxide formation (sump, dross)

- Less effort for the disposal of sump and dross

- Better temperature control as well as

- Lower consumption of inert gas

- Longer crucible life

- Better component quality

- Lower maintenance costs (machine downtime, labor)

The system is especially attractive with regard to maintenance and operation because of the

- Simple construction, robust design - few moving parts

- Excellent access to the melting surface through the tilt-swivel mechanism of the sluice

- Generously dimensioned inspection opening

- Simple adaptation to different ingot sizes

- No splashing of molten material during sliding of ingots into the melting shaft

- The feeding of material can occur up to _+90° to the longitudinal axis of the furnace (high flexibility in the set-up of systems)