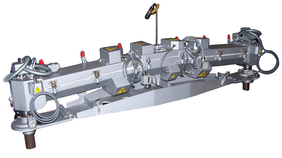

Siphon tube for transfer of Magnesium

Principle of operation:

The tube is installed as a connection between two furnaces. At this time the tube is not filled with magnesium. A vacuum pump incorporates a vacuum in the tube and the magnesium is lifted into the tube. After filling of the tube the magnesium starts to flow according the principle of communicating vessels. The vacuum-pump connection is intentionally frozen and thus blocked to the surrounding atmosphere.

To empty the tube the magnesium in the vacuum connecting point is intentionally molten by a small heating. Argon streams into the tube and the magnesium flows automatically out of the tube into the two furnaces.